Project Description

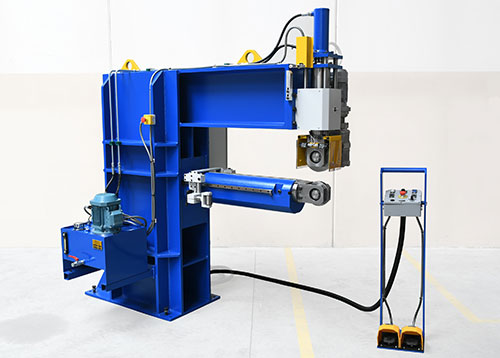

DIMPLE JACKET WELDING MACHINES

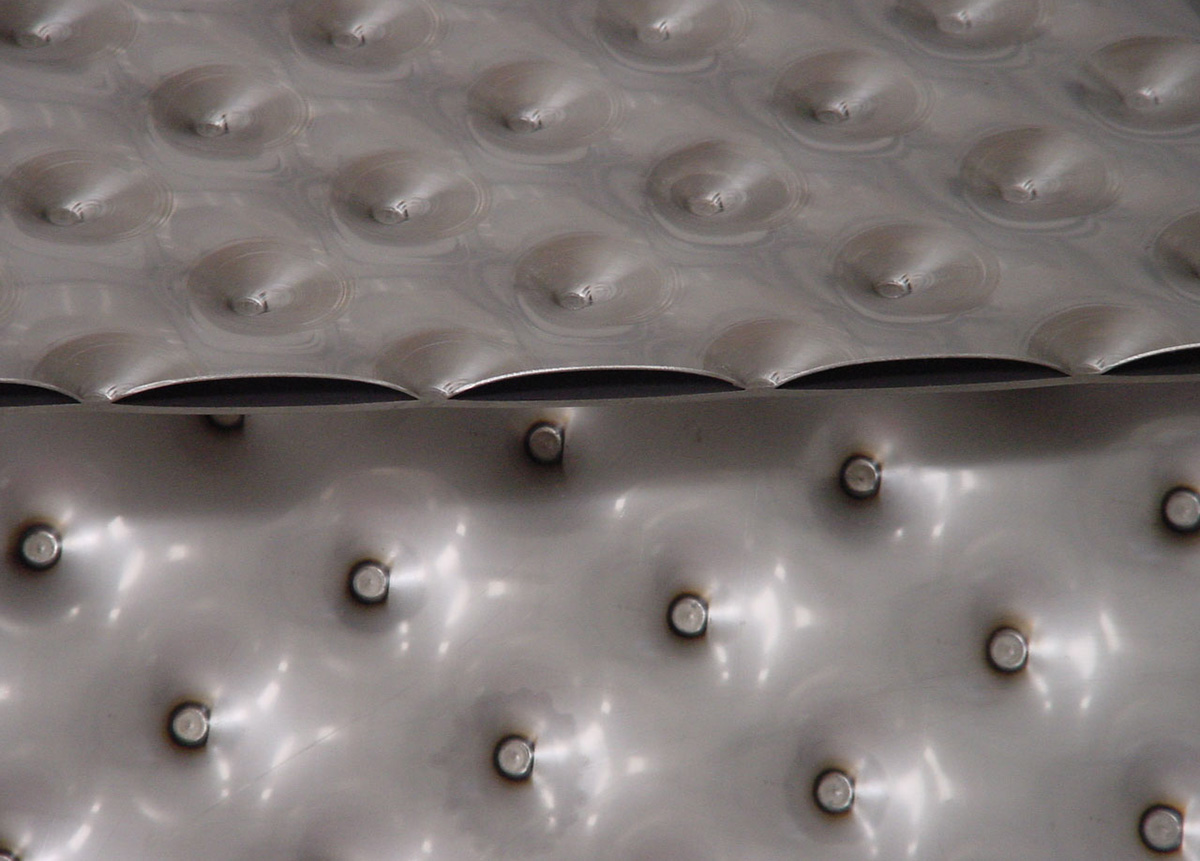

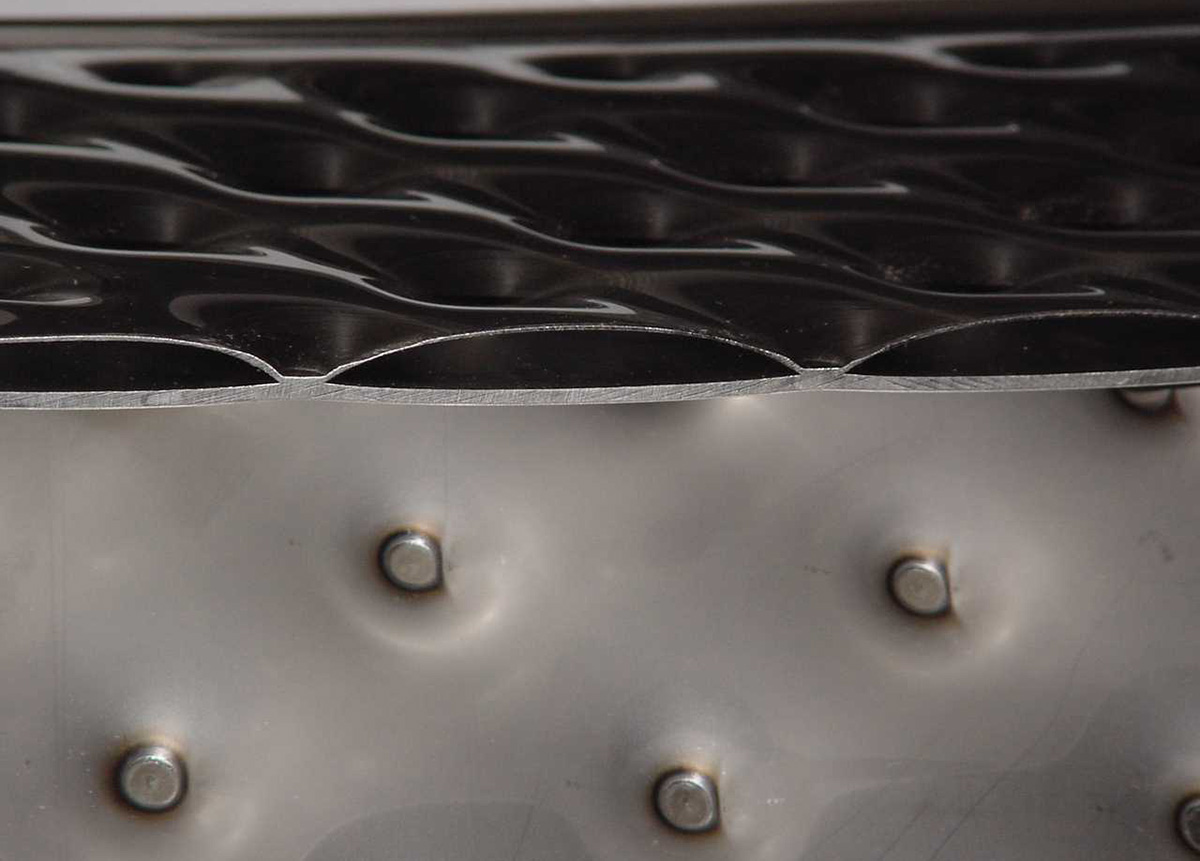

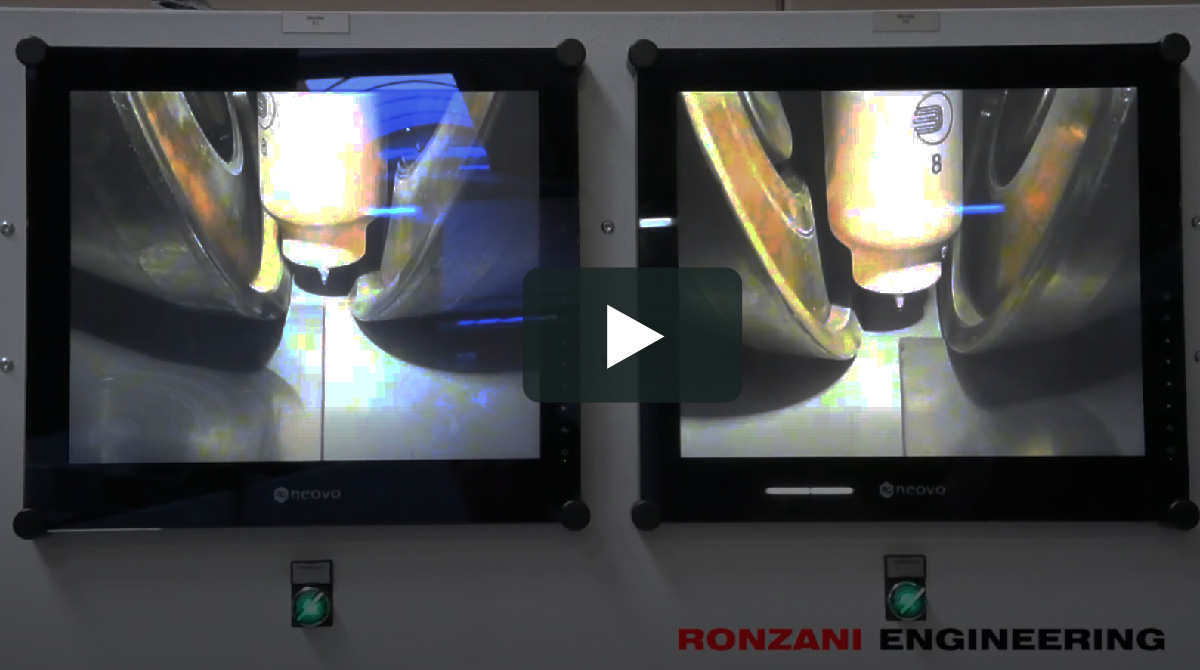

SPOT WELDS WITH TIG OR PLASMA – SEAM WELDS WITH TIG

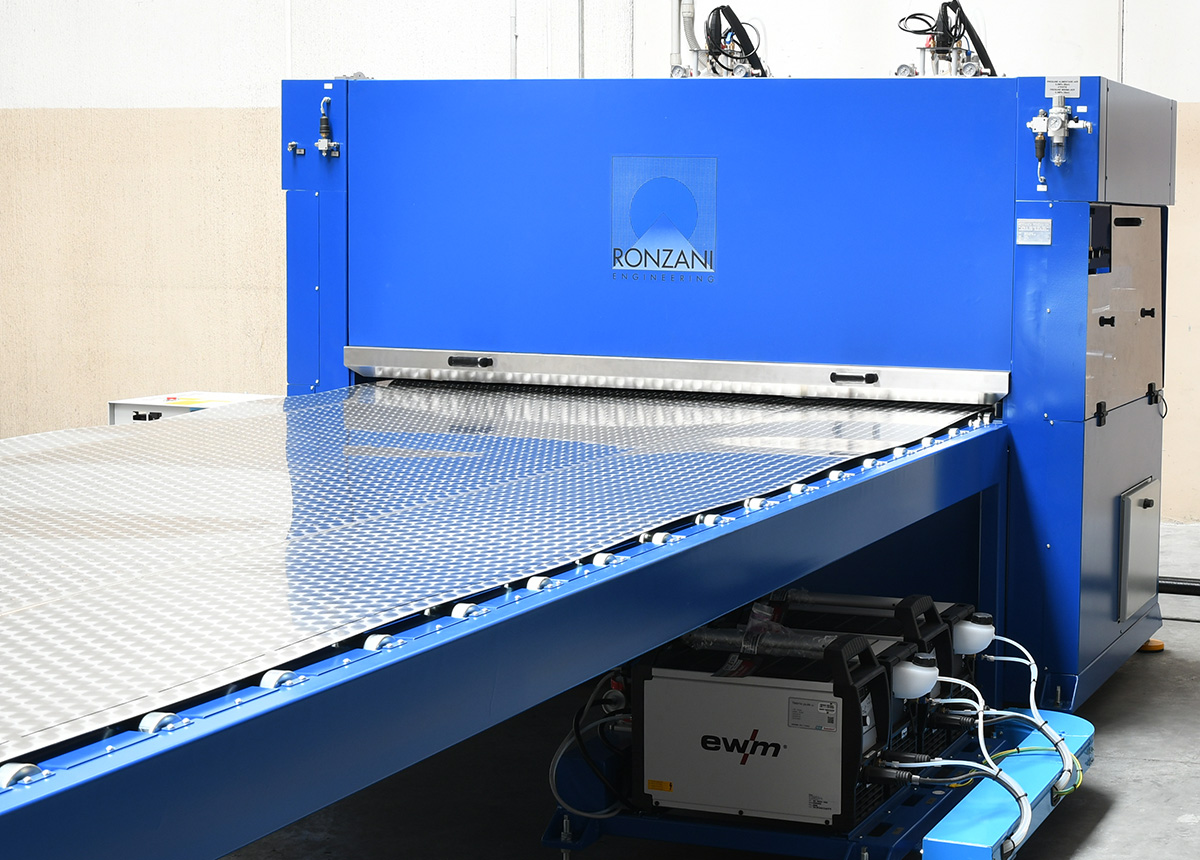

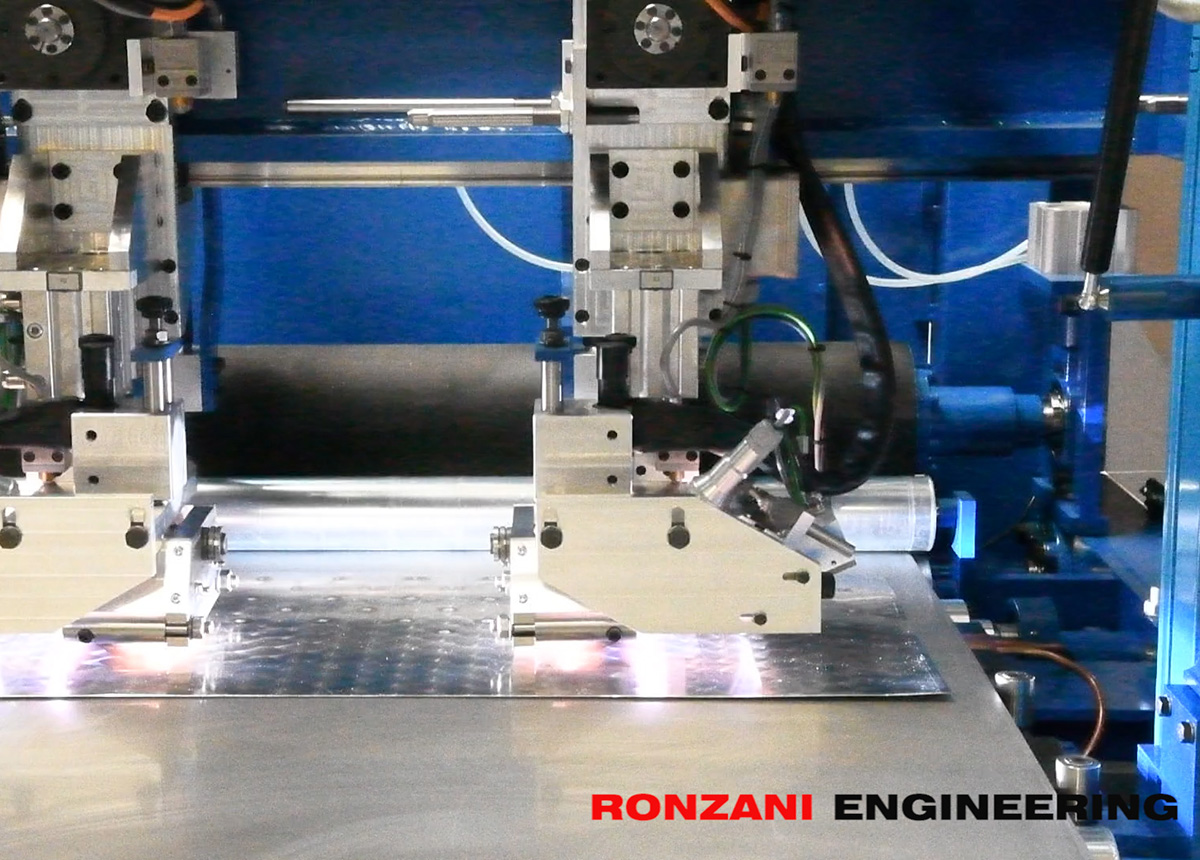

Dimple Jacket Welding Machines

The plant positions the spot-welding units and the sheets to be both spot and edge welded. The welding units are carried on compressed air driven slides for vertical travel and two independent motorized axes for cross-travel. The sheets are transferred by two pairs of motorized rollers that allow sheets of considerable length to be processed.